Exploring the Benefits of UV Silk Screen Ink in Modern Printing Services

In today’s competitive marketplace, businesses must constantly innovate and improve their production processes to stay ahead. One area where significant advancements have been made is in printing technology. Among various printing techniques available, UV silk screen ink has emerged as a game-changer, offering numerous benefits that cater to modern printing needs.

What is UV Silk Screen Ink?

UV silk screen ink is a type of ink used in screen printing that cures quickly under ultraviolet light. This unique characteristic distinguishes it from traditional inks, which typically dry through evaporation. UV inks are composed of a mix of pigments, monomers, and oligomers that allow them to dry almost instantly when exposed to UV light, creating a durable and vibrant finish.

Benefits of Using UV Silk Screen Ink

1. Exceptional Durability

One of the standout features of UV silk screen ink is its incredible durability. Unlike conventional inks, which may fade or scratch over time, UV inks create a hardened surface that resists damage from environmental factors such as moisture and UV rays. This makes them ideal for outdoor applications and products that require a long-lasting finish.

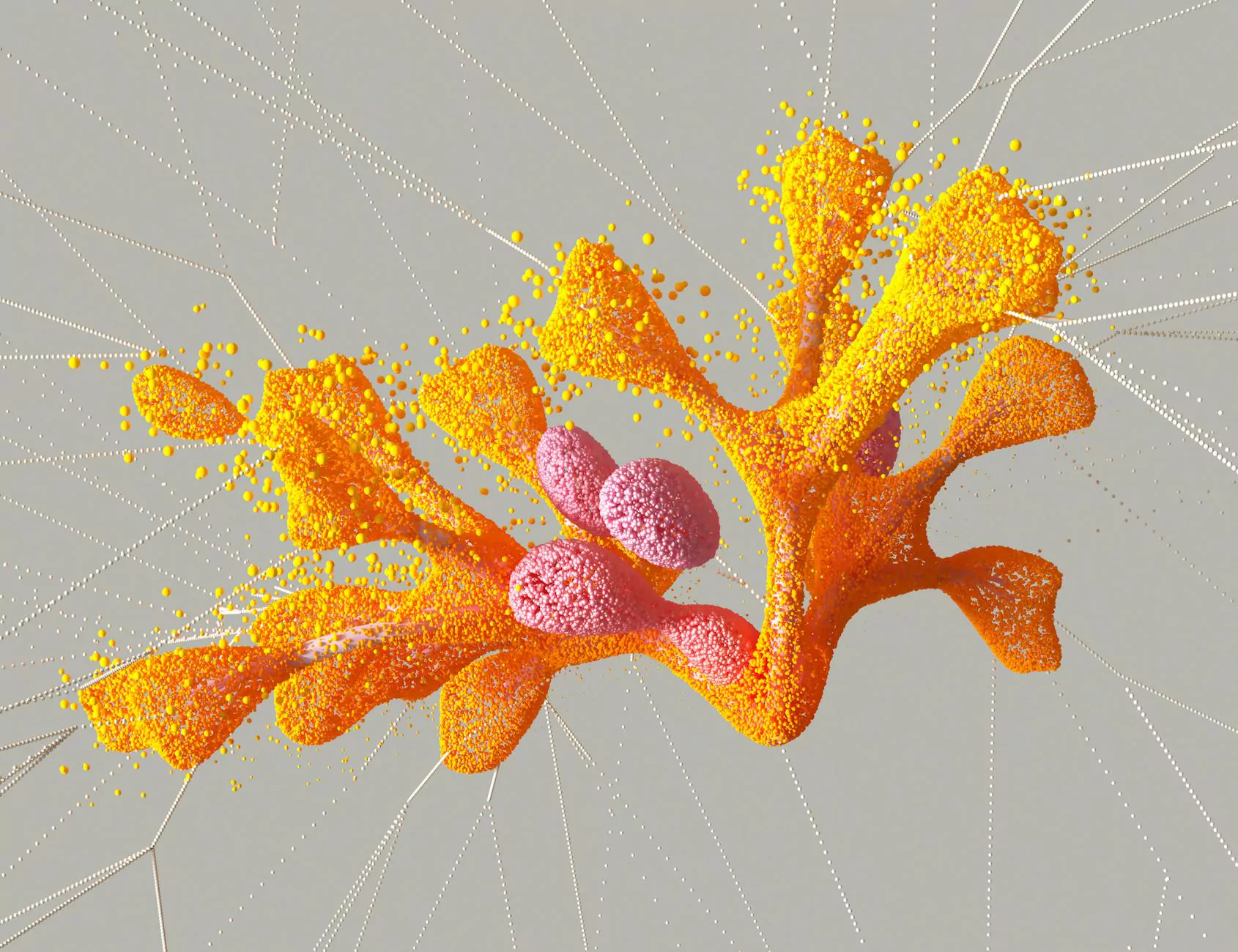

2. Vibrant Colors and Sharp Graphics

UV silk screen ink offers rich and vibrant colors that enhance visual appeal. The formulation of UV inks allows for a wide range of color options, enabling printers to achieve graphics that are not only vivid but also sharp and precise. This makes it especially attractive for brands aiming to create a strong visual impact.

3. Eco-Friendly Option

In today’s environmentally conscious world, the demand for eco-friendly printing solutions is on the rise. UV silk screen ink is solvent-free, making it a sustainable choice compared to traditional solvent-based inks. Additionally, the curing process minimizes volatile organic compounds (VOCs), contributing to a healthier workplace and a cleaner environment.

4. Versatile Applications

Another significant advantage of UV silk screen ink is its versatility. It can be applied to various substrates, including plastics, metals, glass, and textiles. This wide range of applications makes UV silk screen printing suitable for numerous industries, including packaging, automotive, electronics, and more.

5. Quick Turnaround Times

The rapid curing process of UV silk screen ink reduces production times significantly. Printers can achieve quicker turnaround on projects, accommodating tight deadlines without compromising on quality. This speed is particularly beneficial for businesses looking to maintain a competitive edge in fast-paced markets.

How UV Silk Screen Ink Works

1. The Printing Process

The printing process using UV silk screen ink begins with creating a stencil or screen. The desired image or design is placed on the screen, which is then coated with the UV ink. A squeegee is used to push the ink through the screen onto the substrate beneath. Once the ink is applied, it is immediately exposed to UV light, which initiates the curing process.

2. The Curing Process

Curing is a critical step in the operation of UV silk screen ink. The UV light causes a chemical reaction that transforms the liquid ink into a solid, durable film. This process not only ensures that the print adheres well to the substrate but also enhances the ink’s resistance to wear and tear.

Choosing the Right UV Silk Screen Ink

When selecting UV silk screen ink for your printing needs, consider the following factors:

- Adhesion Properties: Ensure that the ink is compatible with the substrate you plan to print on.

- Color Range: Choose inks that offer a wide selection of colors for the most vibrant output.

- Curing Time: Evaluate the curing time to align with your production schedule.

- Environmental Impact: Opt for eco-friendly options to align with sustainability goals.

Applications of UV Silk Screen Ink

The applications of UV silk screen ink are vast and varied, showcasing its adaptability across different industries:

1. Packaging

In packaging, UV inks are used to print vibrant graphics on boxes, labels, and films. The durability of the finish ensures that the packaging maintains its quality throughout the supply chain.

2. Textiles

UV silk screen ink is increasingly used in the textile industry, allowing for high-quality prints on fabrics that are resistant to fading and washing.

3. Promotional Products

Promotional items such as drinkware, pens, and bags benefit from the vibrant prints achievable with UV silk screen ink, enhancing brand visibility.

4. Industrial Applications

In industrial settings, UV prints are often used for control panels, equipment labels, and other printed components that require enhanced durability and visibility.

Conclusion

The adoption of UV silk screen ink represents a significant leap forward in the printing industry. With its exceptional durability, vibrant color capabilities, eco-friendliness, and versatility, it provides a reliable solution for businesses looking to elevate their branding and product offerings. At Boston Industrial Solutions, we harness the power of UV printing technology to deliver outstanding results that meet and exceed our clients' expectations. Embrace innovation in your printing services and discover the numerous advantages of UV silk screen ink for your business today!