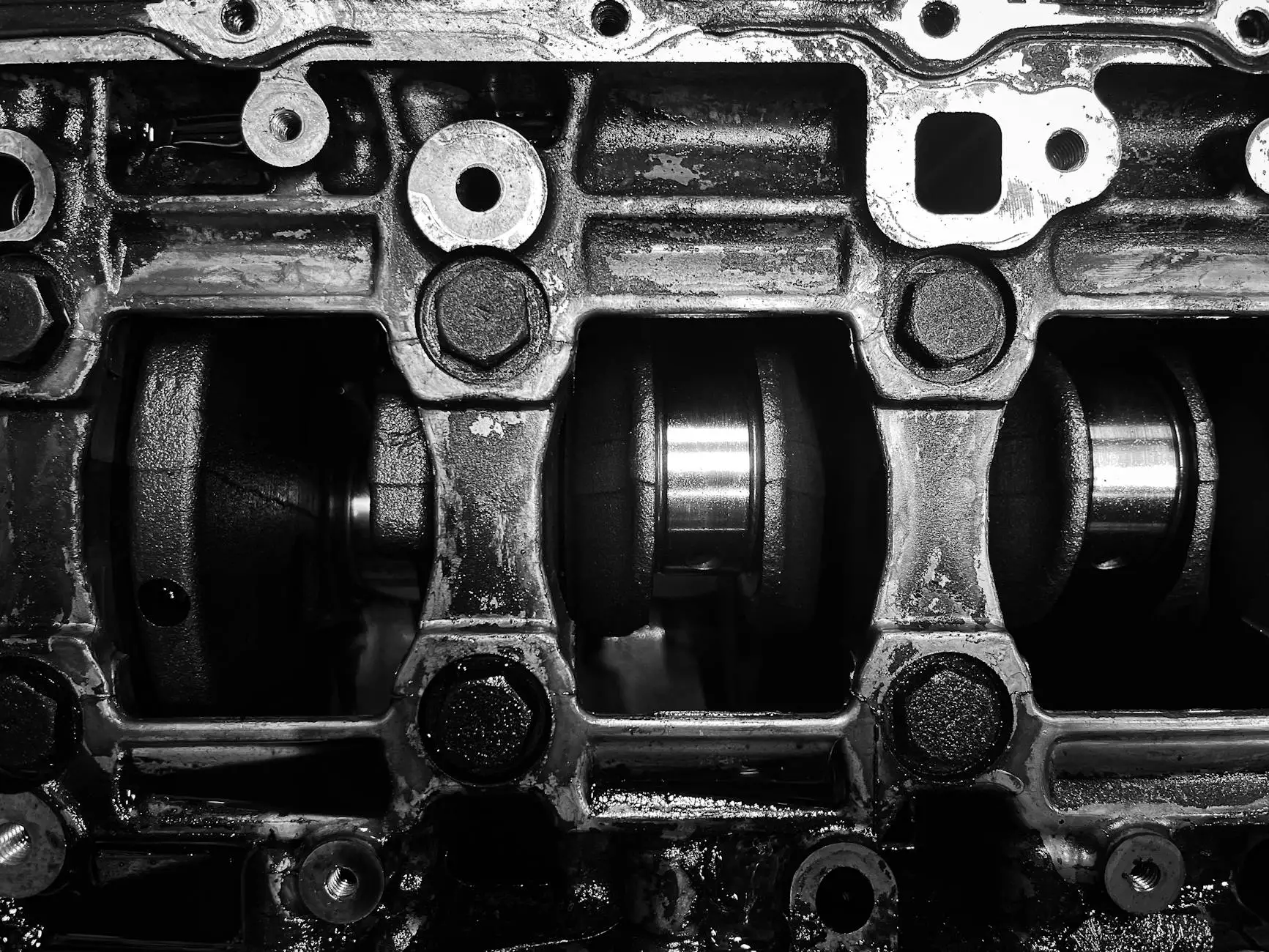

The Crankshaft of an Engine: An Indispensable Component in Diesel Mechanisms

The crankshaft of an engine plays a pivotal role in the dynamic functionality of any automotive vehicle, especially within the realm of diesel engines. Without this quintessential component, the transformation of linear motion into rotational motion necessary for the engine’s operation would be impossible. Understanding the nuances of the crankshaft not only enriches our comprehension of engine mechanics but also guides us in the selection of diesel engine parts for optimal performance.

What is a Crankshaft?

The crankshaft is a crucial mechanical component that converts the reciprocating (linear) motion of the pistons into rotational motion which ultimately drives the vehicle. It is primarily fabricated from strong materials such as forged steel or cast iron, designed to withstand the immense pressures generated during the combustion process.

Key Functions of the Crankshaft

The functions of the crankshaft extend beyond mere mechanical motion. Here are some key roles it plays:

- Converting Motion: The primary role of the crankshaft is to convert linear motion from the pistons into rotational motion that drives the vehicle.

- Balancing Forces: It helps in balancing the forces produced during combustion, ensuring smoother engine operation.

- Supporting Engine Components: The crankshaft supports various ancillary components, such as the oil pump and timing gears, which are essential for the engine's overall functionality.

- Generating Power: It plays a vital role in generating the power required to move the vehicle forward.

Components of the Crankshaft

The crankshaft consists of several integral components that work harmoniously together. Understanding these components gives insight into how they collectively function to enhance engine performance.

Main Journal

The main journal is the portion of the crankshaft that rotates within the engine block. It is crucial for maintaining proper alignment and reducing friction.

Crankpin

Attached to connecting rods, crankpins are the sections that transfer the reciprocating motion of the pistons to the crankshaft.

Counterweights

Counterweights are strategically placed to offset the weight and balance the engine better, reducing vibrations and extending the lifespan of the vehicle.

Flywheel

The flywheel, often attached at the end of the crankshaft, stores rotational energy and provides momentum to the engine during various operating conditions.

The Importance of Quality Crankshafts in Diesel Engines

Diesel engines, known for their durability and efficiency, rely on high-quality components like the crankshaft to ensure optimal performance. Here are several reasons why investing in a quality crankshaft is essential:

- Enhanced Durability: Quality crankshafts are engineered to withstand the higher stress and temperatures associated with diesel combustion.

- Increased Efficiency: A well-manufactured crankshaft improves fuel efficiency by ensuring precise movements between components.

- Reduced Wear and Tear: High-grade materials result in reduced wear, prolonging the engine’s lifespan and minimizing maintenance costs.

Choosing the Right Crankshaft: Factors to Consider

When selecting a crankshaft for a diesel engine, one must consider several factors that influence both performance and compatibility:

Material Quality

Choose crankshafts made from top-quality materials such as forged steel or a high-grade alloy for exceptional strength and durability.

Precision Engineering

Look for manufacturers that utilize advanced machining processes ensuring the crankshaft is engineered to precise tolerances, promoting efficiency and longevity.

Compatibility

Ensure that the crankshaft is compatible with your specific diesel engine model and other components to prevent operational issues.

Supplier Reputation

Opt for suppliers with a solid reputation in providing quality engine parts, such as client-diesel.com, to ensure peace of mind regarding the reliability of your purchase.

Maintenance Tips for a Healthy Crankshaft

To prolong the lifespan of the crankshaft and optimize engine performance, implementing proper maintenance practices is vital:

- Regular Oil Changes: Maintaining clean oil helps minimize wear on crankshaft surfaces and prevents overheating.

- Monitor Engine Performance: Keep an eye on engine sounds and vibrations, as unusual changes may indicate crankshaft issues.

- Use the Right Fuel: High-quality diesel fuel can help maintain proper combustion, reducing the stress on the crankshaft.

- Inspect Components: Regularly inspect associated components like connecting rods and bearings, as they directly affect crankshaft performance.

Conclusion: Investing in Quality for Long-Term Performance

The crankshaft of an engine is more than just a mechanical component; it embodies the essence of power and efficiency in diesel engines. Understanding its structure, function, and the importance of maintenance will not only empower you as a vehicle owner but also guide your purchases from reputable suppliers like client-diesel.com. Investing in quality crankshafts and engine parts can lead to significant benefits, including enhanced durability, efficiency, and longevity, ensuring your diesel engine operates at its best for years to come. Embrace the knowledge shared here and take the necessary steps to prioritize the maintenance and quality of your engine components, particularly the crankshaft, for a smoother driving experience.