Unlocking Innovation with SLS Technology: The Future of Art Supplies, Product Design, and 3D Printing

In the rapidly evolving world of manufacturing and design, SLS technology (Selective Laser Sintering) stands out as a groundbreaking process that is pushing the boundaries of what is possible. Its unique capabilities have opened new avenues for artists, product designers, engineers, and manufacturers to create highly complex, durable, and innovative products with unmatched precision and speed. At arti90.com, we are dedicated to harnessing the power of SLS technology to serve the needs of diverse industries—particularly in art supplies, product design, and 3D printing. This comprehensive guide delves into the intricacies of SLS technology, exploring its mechanisms, benefits, applications, future potential, and how it propels industries into a new era of innovation.

What is SLS Technology? An In-Depth Overview

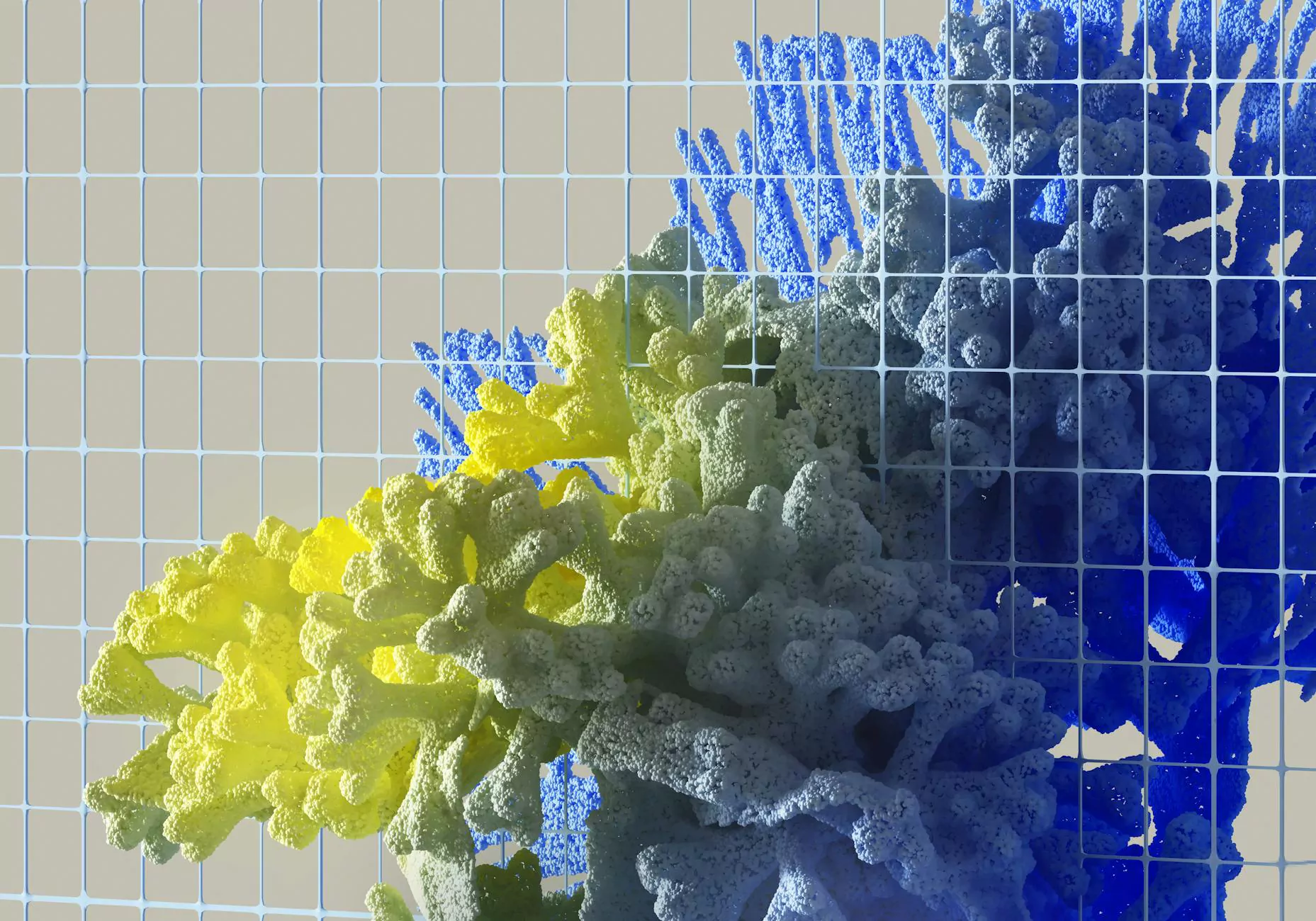

SLS technology refers to a sophisticated additive manufacturing process that uses a high-powered laser to selectively fuse powdered materials—such as plastics, metals, or ceramics—layer by layer to create complex three-dimensional objects. Unlike traditional manufacturing techniques, SLS technology allows for the production of intricate geometries, internal channels, and delicate features directly from digital CAD models.

The process begins with a thin layer of powdered material spread across the build platform. The laser then traces the cross-sectional outline of the part, sintering (fusing) the powder particles that form the outer shell or internal features. After each layer, the build platform drops slightly, and a new layer of powder is spread, repeating the cycle until the object is complete.

One of the defining advantages of SLS technology is its ability to produce parts with excellent mechanical properties—comparable to or exceeding those made through traditional manufacturing—while maintaining high dimensional accuracy and complex geometries.

Advantages of SLS Technology in Art Supplies, Product Design, and 3D Printing

- Complex Geometry Capabilities: Create intricate designs, internal channels, and lattice structures that are impossible to produce with subtractive methods.

- Material Versatility: Suitable for a wide array of materials including nylon, polyamide, metals, and composites, catering to diverse industry needs.

- High Precision and Accuracy: Achieve tight tolerances and detailed features, essential for high-quality art tools, prototypes, and functional parts.

- Rapid Prototyping and Production: Reduce lead times significantly, allowing for swift iteration and faster product launch cycles.

- Cost-Effective for Small and Medium Batches: Minimize tooling costs, making it ideal for short runs, custom art supplies, and bespoke product development.

- Strong and Durable Parts: Produce parts with high mechanical strength suitable for end-use applications, including complex jewelry, art sculptures, and industrial components.

- Eco-Friendly Process: Use only the amount of material needed, with the possibility of recycling unused powder, fostering sustainable manufacturing practices.

Applications of SLS technology in Various Industries

Innovative Art Supplies and Artistic Creations

Artists and artisans are increasingly relying on SLS technology to craft unique sculptures, jewelry, and bespoke artistic tools. The ability to produce highly detailed and complex designs enables new forms of expression and creativity. For example, art supplies such as custom brushes, molds, and intricate decorative elements are now manufactured with precision, enhancing artistic freedom.

Next-Generation Product Design and Prototyping

Product designers leverage SLS technology to quickly create prototypes and functional models that reflect real-world conditions. This accelerates the development cycle, allowing for rapid testing, modification, and validation. Industries such as consumer electronics, automotive, and aerospace benefit from SLS-produced components that are both lightweight and robust.

Advanced 3D Printing for Industrial and Medical Applications

In the medical field, SLS technology enables the manufacturing of custom implants, prosthetics, and surgical guides with unparalleled precision. Its capacity to produce complex geometries facilitates the customization essential for patient-specific solutions. Similarly, in industrial sectors, SLS parts are used for tooling, fixtures, and end-use parts.

Jewelry and Fashion Accessories

The fashion industry benefits from SLS technology by creating intricate, lightweight jewelry designs that are impossible using traditional methods. This innovation allows jewelry designers to push creative boundaries while reducing production costs and lead times.

Transformative Impact of SLS technology on Art Supplies

Modern art supplies are evolving with the integration of SLS technology. Artists can now access tools and materials that were previously unfathomable through conventional manufacturing. Custom brushes, complex molds, and specialized artistic objects can be designed digitally, uploaded, and produced in a matter of hours, thereby opening creative opportunities. For instance, a sculptor can produce multiple iterations of a sculpture with detailed textures, internal supports, and complex curvature — all made possible through SLS technology. This democratizes art creation, allowing artists to experiment freely and reduce costs associated with traditional molds and tooling.

The Future of SLS technology and Its Role in Innovation

The trajectory of SLS technology is poised for exponential growth, driven by ongoing advancements in materials, laser precision, and software capabilities. The integration of artificial intelligence and machine learning is enabling smarter, more efficient printing processes, further reducing costs and increasing quality. Additionally, new materials with enhanced properties—such as high-temperature resistant composites, biodegradable polymers, and metal alloys—are expanding the application horizon of SLS technology. The possibility of printing in multiple materials within a single build is paving the way for fully integrated, multifunctional parts. As industries continue to embrace this technology, we can expect to see a surge in personalized, sustainable, and complex products that were once impossible to manufacture at scale.

Choosing the Right SLS Technology Partner for Your Business

To leverage the full potential of SLS technology, it’s essential to collaborate with a trusted partner that offers cutting-edge equipment, high-quality materials, and expert guidance. At arti90.com, we provide expertise in SLS technology, enabling our clients to transform their design visions into tangible realities efficiently. Our services include:

- Advanced SLS 3D Printing Solutions

- Comprehensive Material Consultation

- Rapid Prototyping and Small Batch Manufacturing

- Custom Art Supplies and Design Tools

- Complex Industrial Components and End-Use Parts

Conclusion: Embrace the Power of SLS Technology to Accelerate Your Business Growth

The integration of SLS technology into your workflows offers unmatched advantages—from comprehensive design freedom and rapid development cycles to high-performance end-use parts. Its transformative impact spans across art, industrial manufacturing, medical fields, and more, shaping a future where creativity and functionality coexist seamlessly. By staying at the forefront of this innovative technology, your business can unlock new levels of productivity, customization, and artistic expression. As leading pioneers in the industry, arti90.com is committed to providing state-of-the-art SLS technology solutions tailored to your unique needs. Embrace the power of SLS technology today and propel your enterprise into a future where innovation knows no bounds.